For the past 6 years, IST has been a trusted provider of CNC machining services, supported by our engineering team. In Q3 of this year, we expanded our capabilities to include welding and fabrication services, specifically for the custom automation equipment we build for our clients. This expansion allows us to create weldments while maintaining our commitment to quality and timely project delivery. With the recent addition to our facility, our total space has now reached 19,600 square feet. This new area enables us to offer even greater value and faster turnaround times to our valued customers.

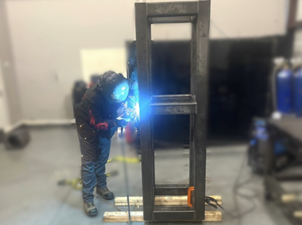

For those new to the weldment process, we’ve created an informative short video highlighting the tasks involved between the hand-off from the final drawing package all the way through the final fabrication. This short video resource is especially insightful for young engineers and technical professionals seeking a better understanding of the steps involved in creating a weldment frame. Check out the IST Welding Video below for a complete step-by-step process.

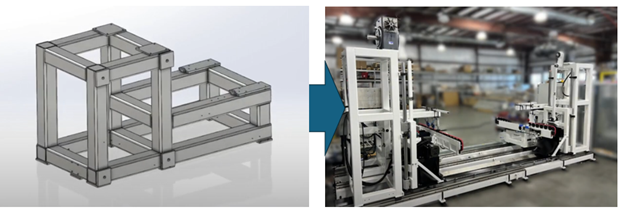

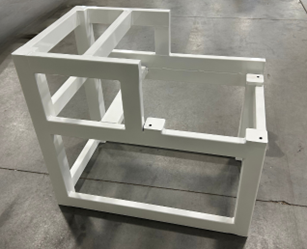

Our fabrication process begins with a thorough review of engineering drawings to ensure all specifications are met and guidelines are followed. Prior to fabrication we collaborate with our customers to select a powder coating color that aligns with their branding or preferences. We then order and prepare the raw materials, adding any necessary features before welding. Our welding table elevates the assembly for easier welding and precise fixture alignment. Following welding, each assembly undergoes inspection and then is sent to a local vendor for powder coating. Once we receive the powder coated weldments from the vendor, we then begin the full machine assembly process. Often this involves adding machine vision, servo stages, and robotic systems. Project timelines for the weldment fabrication typically range from a few days to a couple of weeks.

Currently, the weld shop is equipped with two welding tables and sawing capabilities for steel tubes. Additionally, we have several multi-axis CNC machines to support our welding and manufacturing services. These features, combined with our skilled team, enable us to handle a wide range of projects.

|

|

|

Our welding expertise primarily focuses on TIG/MIG welding for machine frames, ranging from large weldments to small fixtures. IST’s welders not only weld but also support our machine build process with both mechanical assembly and electrical panel assembly. This adaptability ensures our staff can handle various tasks daily, keeping work exciting and diverse.

|

|

During a short span we have used the weldment shop for several structures ranging from precision inspection machine frames to robot pedestals as well as larger scale processing equipment (see two examples below).

|

|

Our expanded facility means more resources, expertise, and ways to help you succeed! Contact us at [email protected] or (704) 782-0593 to get your project started today!